MIXERS & AGITATORS

UTG Mixing Group - SPX Flow

STELZER AGITATOR SERIES F&B

- Compact Agitators SM/SG

Compact agitator series with direct drive mechanism. The mixer is food application approved design. Available in top entry and bottom entry.

The advantages of this mixer is reliable performance even at low torque. Perfect concentricity and quiet operation at all speeds. Sealing technology range from radial shaft sealing with oil drip pan up to high tech hygienic double acting mechanical seal, and also wide range applications.

Motor power available is 0.37 – 15 kW, with shaft diameter 25 – 60 mm.

- Compact Agitators SHS/SHK

Compact agitator series. Driver unit as parallel shaft or bevel helical gear motor, hollow shaft design. Available for top entry or bottom entry. The adventages of this model is reliable performance even at medium to high torque. Motor power available is 0.37 – 55 kW, with shaft diameter 40-125 mm.

- Magnetic Coupled Agitators Hermet

Hermet Mag Drives are used in all industries where products must be handled in a sterile or toxic environment. It is used for blending, suspension, dissolving, gassing and heat transfer application in low to medium viscous media. The system is fit for CIP and SIP and materials have been FDA approved for compliance with current GMP. Driver unit is gearbox with motor or air driven motor. 100% hermetic sealed tank for sterile or toxic processing. Motor power available is 0.12 – 7.5 kW.

- Standard Agitators SNR

Benefits include compact dimensions, very quiet operation and a wide range of sealing and drive systems. Options for top entry, side entry or bottom entry. Fixed or variable speed drive systems as process needs dictate. Lip seal, stuffing box or mechanical seal with DIN Dimensions. This mixer for all ATEX Conditions Zone 0, 1, 2. Motor power available is 1.1 – 110 kW, with shaft diameter 40 – 125 mm.

STELZER COAXIAL SHAFT AGITATOR

Coaxial shaft agitators are double acting units equipped with two agitator systems, each with its own independent drive and control system. The double drive system enables the combination of different process steps, such as blending, suspending, dispersion and heat transfer. This is a cost-efficient alternative to blenders and horizontal mixers. Coaxial agitators are designed to handle viscosities from water-like fluids up to 1 million centipoises in one process. Double acting agitation cases require tailored impellers based on helical blades or other generic impeller designs. The input power range is 1.5 – 160 kW and the shaft diameter range 40-200 mm.

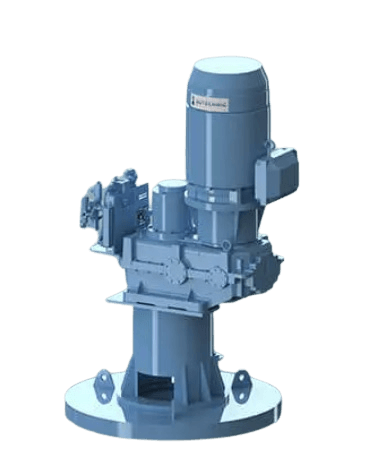

TAILORED HOUSING Type

by UU Technic (an SPX Flow brand)

If modular structures do not fulfil the requirements or DIN standards are not competitive, the drive unit can be fully tailored to fit the purpose. These are normally applied in pressure vessels requiring special sealings and for different sealing and bearings or extra high torque requirements.

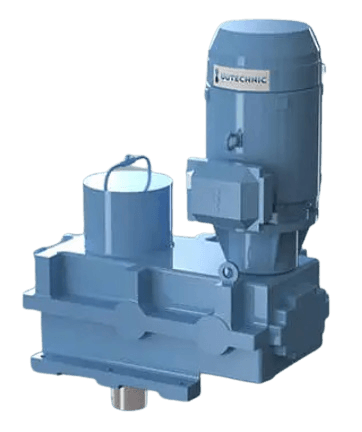

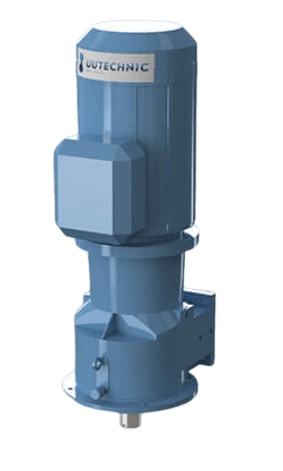

SIDE&BOTTOM ENTRY Mixer

by UU Technic (an SPX Flow brand)

Side entry agitators are designed for high-end performance for the pulp and paper industry. The conical structure of the drive unit minimizes the distance between the impeller and the seal. The short distance means reduced radial loads on the mechanical seal. This drive is always equipped with an industrial gear and can be applied up to 132 kW.

To Get More Information

Don't Hesitate to Contact Us

Company Address

Rukan Kirana Boutique Office

Blok F3 no 12, Boulevard Raya No.1 Kelapa Gading. Jakarta Utara

Indonesia, 14240

Contact

+6221 4585 8833

info@arasains.co.id

Quick Link

Product Link

Copyright (c) 2021 PT Arasains. All Right Reserved