POSITIVE DISPLACEMENT PUMP (NON SANITARY)

NON SANITARY PUMP

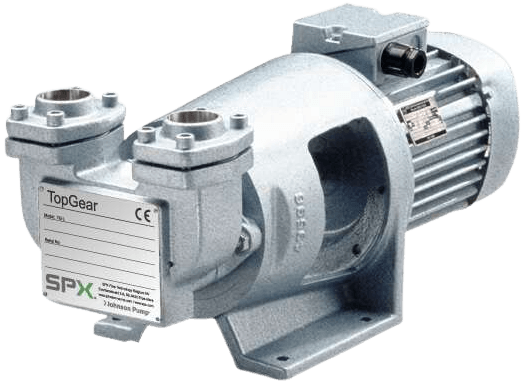

Top Gear Magnetic Drive Internal Gear Pump

by Johnson Pump (SPX Flow)

TopGear MAG is a range of leak-proof internal gear pumps for low and high viscous liquids which are corrosive, toxic, aggressive or expensive. Total containment of the liquid inside the pump is achieved using a hermetically sealed can, which isolates the liquid from the surrounding environment. This eliminates the need for shaft seals and the associated wear and leakage that would normally be experienced.

SPECIFICATIONS:

| Casing: | Cast steel, Stainless steel |

|---|---|

| Idler: | Cast iron, Stainless steel, Steel |

| Rotor: | Stainless steel, Carbon steel |

| Max. differential pressure: | 80 m³/h |

| Max speed: | 16 bar |

| Max. temperature: | 260°C |

Top Gear L Internal Gear Pump

by Johnson Pump (SPX Flow)

TopGear L-series is available in six different sizes. Shaft seal options include mechanical seals, packed gland and double flushed PTFE lip seals. Flange-mounted or bracket for foot-mounting, the TG L pedestal fits to IEC-flanged motors. Safety relief valves are available built-on or separately. Connection sizes from 1" to 1.1/2".

SPECIFICATIONS:

| Casing | Nodular cast iron One size in stainless steel |

|---|---|

| Idler: | Steel |

| Rotor | Steel |

| Max. capacity: | 8 m3/h |

| Max. differential pressure: | 25 bar |

| Max. temperature: | 250°C |

| Max. viscosity: | 60000 mPas |

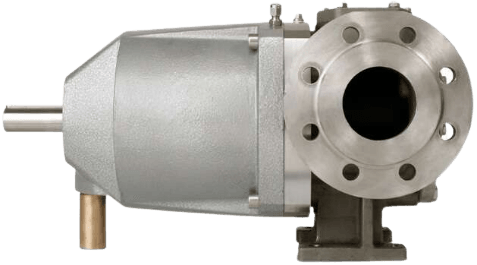

Top Gear H Internal Gear Pump

by Johnson Pump (SPX Flow)

TopGear H-series is available in nine different sizes. The modular design gives a wide range of possibilities. Shaft seal options include single and double mechanical seals as well as packed gland and cartridge seals. Heating and cooling jackets are available for pump cover and around shaft seal.Base plate-mounted.

SPECIFICATIONS:

| Casing | Cast steel, Ductile iron, Stainless steel |

|---|---|

| Idler: | Cast iron, Stainless steel, Steel |

| Rotor | Cast iron, Nodular iron, Stainless steel |

| Max. capacity: | 130 m3/h |

| Max. differential pressure: | 16 bar |

| Max. temperature: | 300°C |

| Max. viscosity: | 80000 mPas |

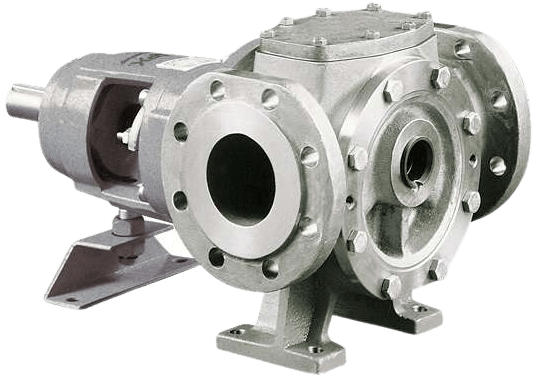

Top Gear Bloc Internal Gear Pump

by Johnson Pump (SPX Flow)

The new Johnson Pump TopGear Bloc close-coupled gear pumps in cast iron and stainless steel utilize the proven hydraulics of the TopGear range. For low/medium-viscous, clean and non-abrasive liquids.

SPECIFICATIONS:

| Casing | Cast Iron and Stainless Steel |

|---|---|

| Idler: | Hardened Steel or Nitrided Stainless Steel |

| Rotor | Nodular Iron or Stainless Steel |

| Max. capacity: | 50 m3/h (220 GPM) |

| Max. differential pressure: | 16 bar (232 psi) |

| Max. temperature: | 180°C (356°F) |

| Max. viscosity: | 7500 mPas/cP |

Top Lobe – Rotary Lobe Pump

by Johnson Pump (SPX Flow)

Tri-lobe rotary lobe pump, designed to handle most applications in today’s processing industries.

BENEFITS:

- Simple, clean and robust construction - Hygienic, minimum risk of product entrapment, easy to clean either by CIP, SIP or manually, short cleaning downtimes

- Easy maintenance - Easy service and maintenance, simple gearbox construction

- Gentle product handling - Traditional tri-lobe design gives gentle handling, low pulsation and capability of handling particles

- Large selection of shaft seals - Easily interchangeable with other seal types, short downtimes

- Shim-free, oil lubricated gearbox - Easy to service, longer life

- ATEX Certified and CE Certified

SPECIFICATIONS:

| Rotor case: | Stainless steel 316L |

|---|---|

| Rotors: | Duplex stainless steel, FPM, Nitrile rubber |

| Max. capacity: | 125 m3/h |

| Max. working pressure: | 22 bar |

| Max. speed: | 1400 rpm |

Top Lobe Plus – Rotary Lobe Pump

by Johnson Pump (SPX Flow)

Pump features is smooth flow, gentle product handling, dry running ability with double seal, handles low and high viscosity products. The pump is simple maintenance, hygienic design, low sound level, CIP capability standard, free draining pump housing. Large fluid cavities can pump liquids with large solids. Pumps are energy efficient and easily cleaned, maintained and repair. ATEX Certified and CE Certified

SPECIFICATIONS:

| Rotor case: | Stainless steel 316L |

|---|---|

| Rotors: | Stainless steel 316L |

| Max. capacity: | 1371 l/min |

| Max. working pressure: | 10 bar |

| Max. speed: | 1200 rpm |

Top Air – AODD Pump

by Johnson Pump (SPX Flow)

The TopAir series is one of the most complete lines of Air Operated Double Diaphragm pumps on the market. With eight sizes up to 800 l/min in a wide range of material combinations we can offer pump solutions for all types of applications and industries.

Typical characteristic of this pump are self-priming, applicable for high and low viscosity product, dry running capability, solids and polluted liquids, variable flow, wide range materials, and easy maintenance.

SPECIFICATIONS:

| Materials: | PP, Aluminium, Stainless Steel, Cast Iron, PTFE, PVDF, PVC |

|---|---|

| Max. capacity: | 48 m3/h |

| Max. pressure: | 7 bar |

| Max. temp: | 120°C |

| Max. viscosity: | 80000 mPas |

FIP – Flexible Impeller Pump

by Johnson Pump (SPX Flow)

Industrial flexible impeller pump for standard and hygienic applications. Polished stainless steel for hygienic applications. Industrial stainless steel for standard, non-sanitary applications. Bronze for non-corrosive duties

SPECIFICATIONS:

| Pump body: | Stainless steel, Bronze |

|---|---|

| Impeller: | FDA-approved EPDM, Neoprene, Nitrile |

| Max. capacity: | 30 m3/h (495 l/min) |

| Max. pressure: | 4 bar |

| Max. temperature: | 55°C (higher for cleaning) |

| Self-priming up to:: | 5 m |

Filters Pump

by Johnson Pump (SPX Flow)

Johnson pump filters are important for smooth operations of positive displacement pumps. These remove unwanted debri which can damage the rotors. Johnson Pump supplies Top filters in two ranges, four material options and eleven separate sizes with a mesh size down to 10 microns. The filters are available in single or dual filter models. The dual filter option allows one basket to be cleaned when switched off line.

Frequently Asked Questions

-

What is the advantage of using lobe pumps over progressive cavity pumps?

Progressive cavity pumps usually have wear on the rubber stator especially if the fluid pumped is abrasive. Lobe pumps do not touch the stator when running and the material can be hardened for abrasive materials

-

What is the advantage of gear pumps over lobe pumps?

Gear pumps are usually used for pumping high viscosity fluids where there is no problems with shear e.g. in pumping bitumen. The gear pumps run at higher speeds and are smaller and thus cheaper.

-

When should the single cavity lobe pumps be used?

single cavity lobe pumps are used where there are very high viscosity fluids which contain abrasives e.g. sugar molasses

To Get More Information

Don't Hesitate to Contact Us

Company Address

Rukan Kirana Boutique Office

Blok F3 no 12, Boulevard Raya No.1 Kelapa Gading. Jakarta Utara

Indonesia, 14240

Contact

+6221 4585 8833

info@arasains.co.id

Quick Link

Product Link

Copyright (c) 2021 PT Arasains. All Right Reserved