POSITIVE DISPLACEMENT PUMP (SANITARY)

SANITARY PUMP

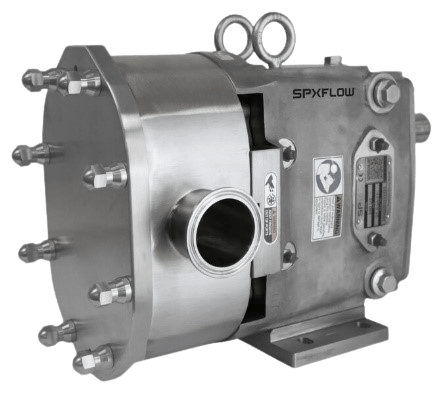

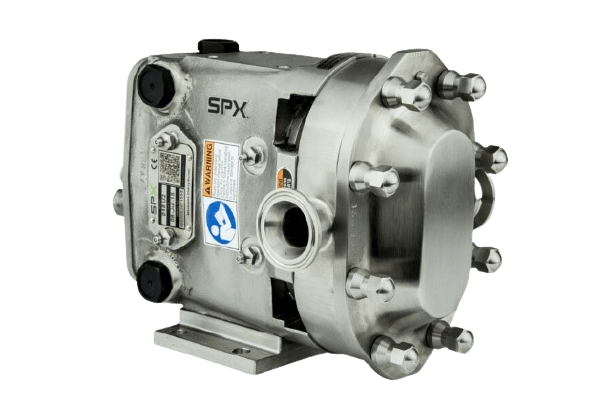

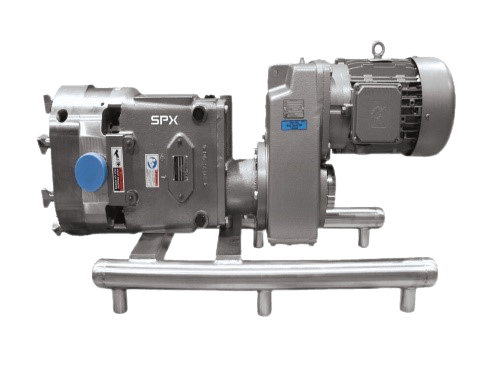

Universal 3 Series

by Waukesha Cherry-Burrell (SPX Flow)

Universal 3 Series positive displacement pumps are engineered to perform in food & beverage, dairy, pharmaceutical, personal care, chemical and industrial industries. This pump is CIP capable standard. Using non-galling Waukesha “88” alloy rotors standard, permits running at tighter clearances and pumping a wide range of viscosities. Stainless steel rotors also available.

The Universal 3 series include a standard stainless steel gear case, the choice of multiple seal options, and bearings that are sealed from the product zone. Front loading seal design make it easy maintenance. Cover seal is a profile design to improve cleanability and resist particulates from being "pinched" and trapped. Universal 3 is available with single mechanical seals standard with optional double mechanical seals, o-ring and lip seals also available. Ability to switch seal types without additional machining.

Many options are available for the Universal 3 series pump including an aseptic configuration with aseptic ports and cover. Universal 3 is up to 500 psi (34.5 bar) pressure capability with pumps rated to 300˚F (149˚C) as standard.

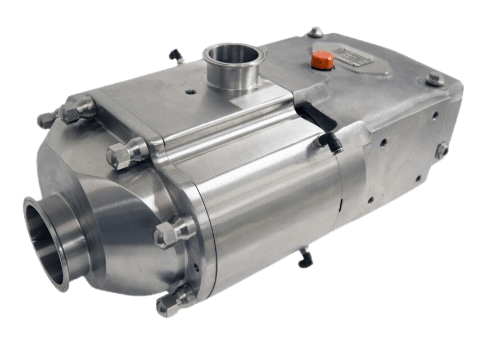

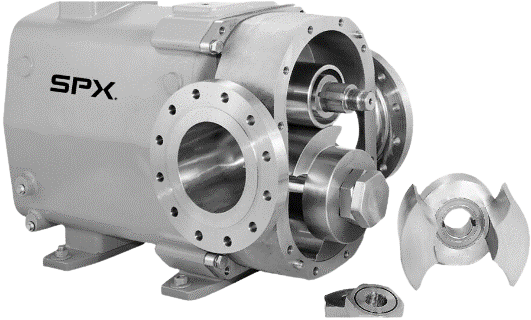

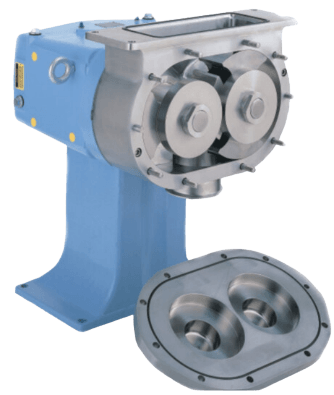

Universal Twin Screw

by Waukesha Cherry-Burrell (SPX Flow)

Universal Twin Screw has reliable performance. Screws made from Waukesha Alloy 88 non-galling material allow the pump to run through incidental contact and reduce risk of pump damage if screws make contact. Gentle product handling to pump large particulates without degradation.

Three screw pitch options for all models offer a wide selection of capacities, pressures, flow rate profiles, and particle sizes. SPX FLOW pump specialists can advise you on the optimal pitch for your application

The pump design is front loaded access to product side seals to make this pump easy maintenance.

Process flexibility - Low inlet pressure requirement and a wide range of operating speeds allow for multiple duties including process and CIP supply. Bi-directional flow capability without making modifications to the pump.

With its high suction capability, the Universal TS Series pump is both process and CIP capable, allowing you to reduce the number of pumps, valves, and control systems in your process and save capital equipment costs.

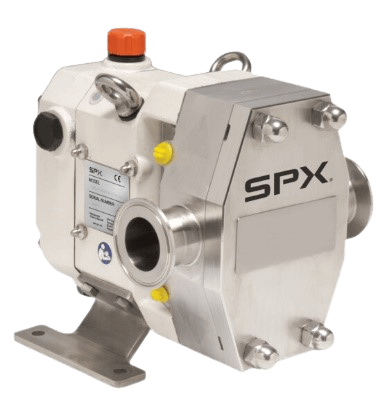

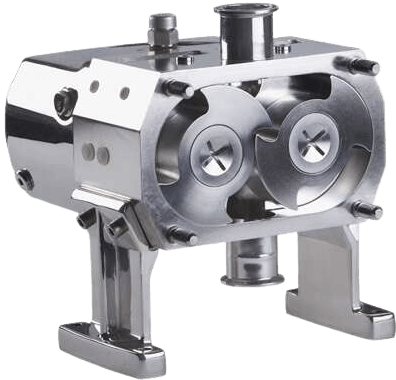

Universal 1 Series

by Waukesha Cherry-Burrell (SPX Flow)

The durable Waukesha Clean-out-of-Place (COP) Positive Displacement "Can-Do Pump". Versatile in application, its reliability has made it the industry standard worldwide. Using Non-galing Waukesha “88” alloy rotors. Easy cleaning and disassembly, flexible with three-way mounting. Seal for Universal 1 is interchangeable single and double "O" ring and mechanical seals. Pump has design with maximum pressure 200 psi (13.8 bar) with temperature range -40°F (-40°C) to 300°F (149°C). Waukesha Cherry Burrell meets 3-A sanitary standard and BISCC approved.

Typical product application for bakery, beverage, canning, confectionery, cosmetics, dairy, meat packing, pharmaceutical & healthcare.

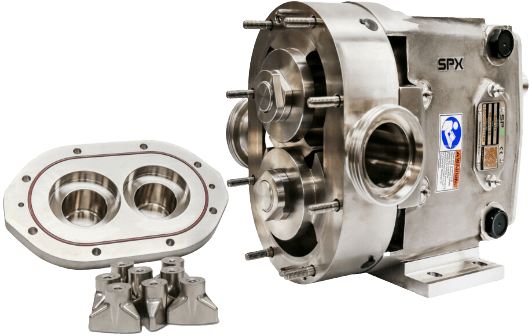

Universal 2 Series

by Waukesha Cherry-Burrell (SPX Flow)

The Waukesha Universal 2 Series positive displacement pumps include advanced sanitation technologies, long life features and installation flexibility. Clean-in-Place (CIP) capable with optional flat body profile and free draining vertical ports. This highly robust pump can run at pressures of up to 500 psi (34.5 bar). Using Non-galling Waukesha “88” alloy rotors standard permits running at tighter clearances and pumping a wide range of viscosities. Single mechanical seals standard with optional double mechanical seals also available. 316L stainless steel lobe rotors also available. Rotor/shaft connection sealed from product zone. 316L stainless steel pump body and cover with Jacketed or vented cover as optional.

Typical product application for food and beverage, dairy, pharmaceutical & cosmetics, chemical & industrial.

MDL Series

by Waukesha Cherry-Burrell (SPX Flow)

MDL Sanitary Rotary Lobe Pump with optimal efficiency. Smooth flow, gentle product handling, dry running ability with double seal, and able to handles low and high viscosity product is operational feature that offered by this pump. The pump is CIP able standard, the rotor material is SS316. Pumps are energy efficient and easily cleaned, maintained and repaired. The Medium Duty Lobe series is available in 9 different sizes. Shaft seal options include single mechanical, quenched, double flushed. Feet for vertical or horizontal mounting. Differential pressure rating up to 10 bar (145 psi).

Universal 1 Series 420/520 High Capacity

by Waukesha Cherry-Burrell (SPX Flow)

Positive Displacement Pumps designed to overcome the challenge of accurate pumping at high-volume capacities. Every revolution of the 420 pumps more than 1 gallons (6 liters); the 520, more than 2 gallons (8 liters). Ideally suited for tomato, vegetable and pet food industries and for chemical/industrial applications. This pump using Non-galling Waukesha "88" alloy rotors; 316L stainless steel rotors optional. Rotor/shaft connection sealed from the product zone. Seal replacement from the front without removing pump body. Pump has design with maximum pressure: 150-200 psi (10.3-13.8 bar) and temperature range: -40°F (-40°C) to 300°F (149°C).

Universal 2 Series Automotive Paint Pump

by Waukesha Cherry-Burrell (SPX Flow)

A modification of the Universal 2 Positive Displacement Pump. This pump is manufactured specifically for paint re-circulation in the automotive industry. This pump using Non-galling Waukesha "88" alloy rotors, permit running at tighter clearances and pumping a wide range of viscosities. Pump has maximum pressure: 200-300 psi (13.8-20.7 bar), depending on model and temperature ranges: -40°F (-40°C) to 300°F (149°C)

Benefits of this pump as below:

- Protects water-borne shear sensitive paints

- Pigments are not separated, which can change viscosity and cause color shifts

- Aluminium and mica metallic flakes are not damaged, which result in deep rich paint luster and shiny finish

- Substantial energy cost savings compared to turbine and piston pumps

- Pump are energy efficient and easily cleaned, maintained and repaired.

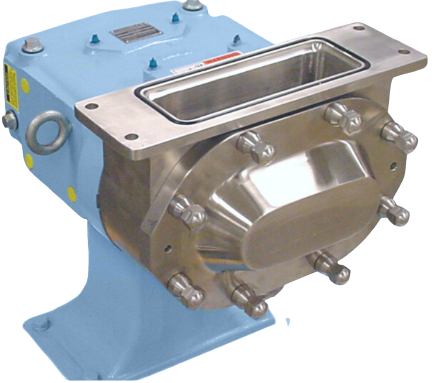

Universal 2 Series Rectangular Flange Model

by Waukesha Cherry-Burrell (SPX Flow)

Specifically designed to pump "unpumpable" products, such as dough, meat emulsion, puddings and cheese, that cause bridging and cavitation in conventional pumps. Pump design with large rectangular inlet port, with 316 stainless steel body using Non-galling Waukesha "88" alloy rotors Six models feature inlet ports ranging in size from 7.13 to 86.87 square inches. Maximum pressure: 200 psi (13.8 bar)* and temperature range: -40° F (-40° C) to 300° F (149° C).

Universal 1 and 2 Series- Tru-Fit Models

by Waukesha Cherry-Burrell (SPX Flow)

Tru-Fit models are available for U1, U2, Lobe and Twin Screw (UTS) positive displacement pumps. Tru-Fit pump model advantages include: No shaft alignment necessary, no coupling guard required and ease of maintenance. Reduces overall length of complete unit by an average of 20-25%. Average of 10-20 gear ratios available per horsepower. NEMA or IEC frames available, right angle reducer also available for additional space savings. 1/2 through 60 horsepower drive options available. Available for models 006 through 320 U1, U2, UL.

Universal 1 Series Rectangular Flange Model

by Waukesha Cherry-Burrell (SPX Flow)

Specifically designed to pump "unpumpable" products, such as dough, meat emulsion, puddings and cheese, that cause bridging and cavitation in conventional pumps.

Pump design with large rectangular inlet port, 316 stainless steel body using Non-galling Waukesha "88" alloy rotors. Maximum pressure: 200 psi (13.8 bar)* & Temperature range:-40° F (-40° C) to 300° F (149° C). Pump available in 7 models.

Top Wing – Rotary Lobe Pump

by Johnson Pump (SPX Flow)

Heavy duty Ultra-hygienic rotary lobe pump designed for the most demanding applications. The pump has feature superior hygiene - Self-draining rotor case and mechanical seal assembled in the liquid. Low carbon stainless steel with smooth surfaces. Easy to clean CIP, SIP or by hand, with a minimum of entrapped liquid.

Pump can easily be validated in to Ultra-hygienic applications. Rotors with smooth performance and minimized back slip, able to handle particles. Front-loaded product seals and robust bearing assembly without shimming, easy maintenance. Different clearance classes Depending on temperature, pressure and viscosity. Multi rotors or BiWing rotors Optimal performance

SPECIFICATIONS:

| Rotor Case : | Stainless steel 316L |

|---|---|

| Rotors : | Duplex stainless steel |

| Max capacity : | 156 m3/h |

| Max working pressure | 15 bar |

| Max speed: | 1400 rpm |

Video

To Get More Information

Don't Hesitate to Contact Us

Company Address

Rukan Kirana Boutique Office

Blok F3 no 12, Boulevard Raya No.1 Kelapa Gading. Jakarta Utara

Indonesia, 14240

Contact

+6221 4585 8833

info@arasains.co.id

Quick Link

Product Link

Copyright (c) 2021 PT Arasains. All Right Reserved