DRYER- SEJITECH

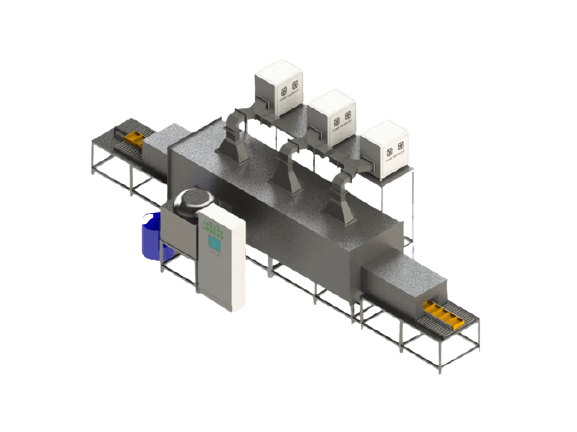

Continuous Microwave Hybrid Dryer - Sejitech

This model utilizes the conventional principles and the microwave drying uses volumetric heating rather than surface heating.

As shown in the figure, this model discharges moisture from the inside of the materials being dried. This shows a large difference in efficiency from the conventional heat method that dries only the exterior.

FEATURES

- Outstanding energy savings

The conventional heat drying method dries the object from the outside and let the heat reach the inside via heat transfer to blow water vapor. However, the microwave drying method transfers heat from the inside. This method allows highly efficient drying effects within only short time range. Therefore, energy saving effect is indeed great. Compared to the conventional heat drying method, the thermal efficiency can be increased up to 30% or more according to the usage conditions.

- Reduced equipment size

Thanks to highly efficient drying process, the continuous dryer can reduce the length of the equipment up to 1/3 compared to conventional heat dryer, which allows for efficient space utilization. Comparing the size by the area that it takes, the microwave dryer requires only 42m2 area, while the conventional heat dryer requires an area of 400m2 for equivalent drying results.

- Improved product quality

Rapid and uniform drying reduces the likelihood of surface overheating, surface hardening, and cracking due to drying stress. During food processing, the dryer shows excellent effects on the maintenance of color and fragrance. Furthermore, the shortening of the drying process timespan does not give time for bacteria growth, so there is no need for fumigation or other chemical treatments to eliminate bacteria.

- Less operation costs

Because the dryer size is reduced and the timespan is reduced, it is easier to stop or restart the system for facility adjustment, product change, cleaning and maintenance. This advantage leads to the reduction of operation costs.

APPLICATIONS

This facility can be applied to drying of insulating materials, drying of agricultural, marine products, drying of paste products (food), drying of particles for chemical industry, etc.

Smart Microwave Compound Dryer - Sejitech

The Smart Microwave Compound Dryer operates with enormously higher efficiency compared to general dryer.

FEATURES

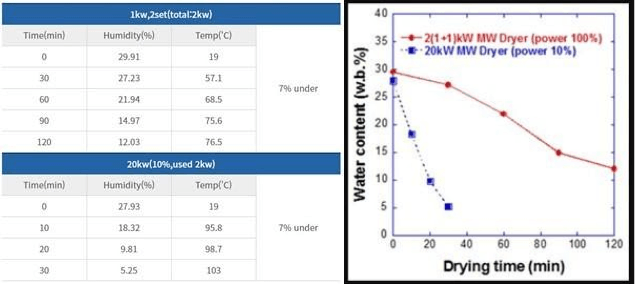

1. Application of mid-end microwave output variable heating type (20kW)

a) Problems of the conventional microwave drying machine

Currently, most of the mw drying machines used in Korea are equipped with small magnetron below the power of 1kw ~ 3kw. When one small magnetron is installed, the users can get the desired results. However, when several magnets are installed, both efficiency and stability become poorer.

b) Effective side-by-side comparison with traditional small microwave dryers’ materials.

c) Multiple Small Microwave Dryer and Economical Comparison

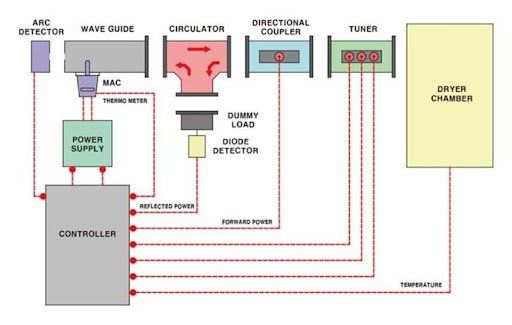

The following figure is the basic structure of microwave:

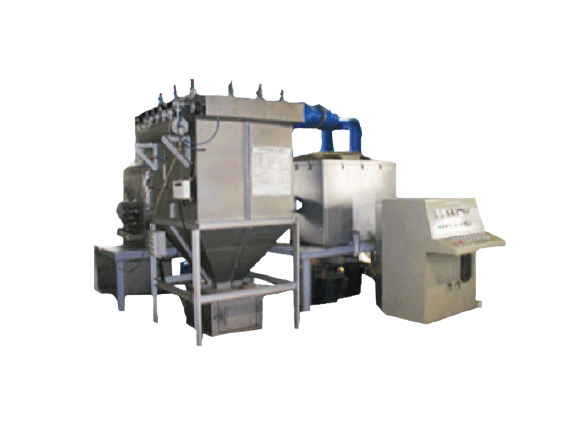

Non-Gravity Fludized Dryer - Sejitech

Principle of Drying

The air generated from the air blower is converted into hot air through the heating units (heater, etc.). This air is mixed with the materials to be dried in the dryer to form supersaturated steam. This steam then passes through the bag filter (dust collector), and again passes through the cooler (refrigerating machine). Within the cooler, the supersaturated steam eliminates moisture due to the temperature difference, and the circulation system allows air without the moisture to move to the air blower again and back to the heating units.

Closed Loop System

Since the drying process is completely sealed, the drying can be done with water contents up to 0.01% without energy release, environmental pollutants release and dust generation. In addition, moisture can be collected in the heat exchanging part, which is very advantageous if using expensive raw materials. Furthermore, it is possible to add specific fragrance to the materials to be dried. Because the process is sealed, the unique taste or fragrance can be maintained (indeed, the system can be opened according to the demand of the user)

Homogeneous Drying

In the inner mixing units, the materials being dried are repeatedly contacted with heat through fluid movements. Accordingly, all materials inside are homogeneously dried, and with the soft action of the machine, the materials can be dried without any damage.

High Efficiency System

Since the drying per unit time is greater compared to that of other dryers, itis a highly efficient drying system.