MIXERS & AGITATOR

LIGHTNIN by SPX Flow

PORTABLE AND FIXED MOUNT MODEL

LIGHTNIN introducing Portable and Fixed Mount Mixer Systems configured to meet your industrial needs. These mixers provide superior economy and value for specific purpose mixing applications. They are ideally suited for a variety of applications from high flow to high shear and for batch or continuous processes.

Lightnin has a modern spectrum of high efficiency impellers which: ■ match specific process requirements ■ reduce capital and operating costs ■ improve process yields .

The standard in tank materials for Lightnin fixed mount mixers is 316 stainless steel. In tank parts are also available in any machinable alloy, or with rubber or plastic coating. Special surface finishes can also be supplied on request.

For some models, with one mixer it is possible to configure a clamp-on, open tank, or sealed mixer design, plus this mixer can be quickly converted from one mounting arrangement to another.

The seal options are:

- The lip seal assembly is designed to prevent the ingress of dust and similar foreign matter into unpressurized vessels. The sealing element is suitable for operation up to 100°C.

- The standard stuffing box is designed for pressures up to 10 bar. It uses 5 rings of packing and split gland follower to provide necessary compression of packing.

- Mechanical Seal : A typical Lightnin seal is a balanced unit which offers positive sealing and is easily maintained. Operation up to 20 bar when lubricated it also has a dry running capability. Double balanced mechanical seals and the most special sealing arrangements can also be accomodated.

Available Model : EV Series, ECL Series, Classic Series, I-Series, S-Series, Series L.

SERIES COMPACT – LIGHTNIN (SPX Flow)

The New Compact Series Mixers by Lightnin offers great value. It has the same high mixing performance as all of our mixers, but at an affordable price.

With its simplified design, the Compact Series benefits from a reduced foot print when you compare the gearbox against our other purpose built agitator gearboxes for equal torque capacity. This reduced foot print makes the unit easier to install and reduces the weight on your support structure. Additionally, the design can accommodate either a double or triple reduction without changing the casting, so no change of foot print for change of speed in the same gearbox size. Reduced weight and loads can help save money on support infrastructure.

Compact Series mixers offer great value and high performance for the Water, Mining and Chemical Industries.

It is important to us that we continue to design and build our own Gearboxes; by doing this we can ensure that all the loads produce mixing your product for your application can be accommodated. We are proud to own our designs.

SERIES 70 – LIGHTNIN (SPX Flow)

The most specified and most proven mechanical design technology in the world makes Lightnin Series 70 Mixers ideal for a wide range of applications. LIGHTNIN Series 70 Mixers cover the range from 1 - 200 hp. They are available in both double and triple reduction gearing, and come in a full range of standard AGMA speeds from 280 down to 16.5 rpm.

Series 70 Mixers offer a full choice of impellers in order to optimize your process results. Included are the high flow A310, as well as other high performance and more traditional impellers, so we can match shear and flow to your process requirements exactly.

SERIES 80 – LIGHTNIN (SPX Flow)

The most specified and most proven mechanical design technology in the world makes Lightnin Series 80 Mixers ideal for a wide range of applications.

Series 80 mixers are especially recommended for processes with high fluid forces on the impellers and long impeller shaft applications.

Series 80 Mixers are a highly efficient heavy-duty mixer, suitable for use in a wide range of applications like Aeration, High Solid Concentration (Mineral Processing), Tall Tanks, Gassed Processed.

Series 80 models for open tanks require minimum headroom to simplify installation.

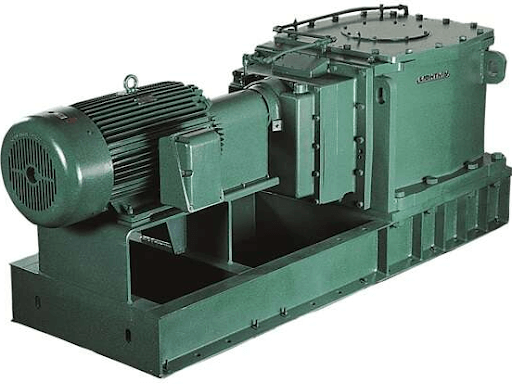

SERIES 700/800 – LIGHTNIN (SPX Flow)

Lightnin 700/800 Mixers are designed to provide reliable service in the largest, most demanding applications, from pharmaceutical fermentation and large-scale chemical processing to minerals processing and heavy sludge waste treatment.

The 700/800 series has the capacity to drive long overhung mixer shaft without steady bearing. It has stamina to withstand severe bending and high-torque loads imposed by fluid forces in tank. Shaft 700/800 mixers are larger and stronger. The bearings are sized for an excess of AGMA requirements. Extensive research in conducted to document the limits of shaft and impeller performance under all service conditions.

As a result, you get longer service life with less maintenance. You get our performance guarantee.

SERIES RSE – LIGHTNIN (SPX Flow)

RSE Mixers are designed for easy installation and high-efficiency operation, which means decreased start-up expense and fewer manholes per tank.

FEATURES:

- Rugged shaft support design can withstand all fluid dynamic forces

- Bearings greatly exceed AGMA requirements for durability and long service life

- Shaft bearings are located outside the tank to prevent corrosion and contamination

- Designed for easy maintenance

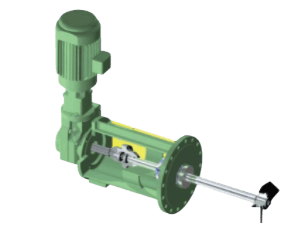

Series LVS – LIGHTNIN (SPX Flow)

Lightnin LVSES series mixers for blending and prevention of solids build-up. High-efficiency LVSES mixers are ideal for a variety of chemical processing, edible oil, petrochemical processing and oil & gas applications.

FEATURES:

- A choice of V-belt and tooth belts to accommodate metric and NEMA frame motors.

- A choice of four sizes optimized for the range of 2.2 to 55 kW.

- Fast and easy seal change to reduce downtime and simplify maintenance. Unlike competitive design, there is no need to loosen the motor support or remove belts, drive pulley and bearings to provide unmatched L10 life exceeding 100,000 hours.

- One-piece cantilever-design output shaft to minimize run out to increase seal life. There are no in tank bearings or sleeves to add to maintenance.

- Standard stainless steel mating faces to eliminate corrosion. Vent valve/check is included to test the shut-off.

- Product lubricated single mechanical seals. Also available are barrier fluid lubricated double mechanical seals for containment of health or environmentally hazardous fluids.

- The exclusive A312 high efficiency impeller.

- LIGTHNIN's 100% performance guarantee.

To Get More Information

Don't Hesitate to Contact Us

Company Address

Rukan Kirana Boutique Office

Blok F3 no 12, Boulevard Raya No.1 Kelapa Gading. Jakarta Utara

Indonesia, 14240

Contact

+6221 4585 8833

info@arasains.co.id

Quick Link

Product Link

Copyright (c) 2021 PT Arasains. All Right Reserved