STATIC MIXERS

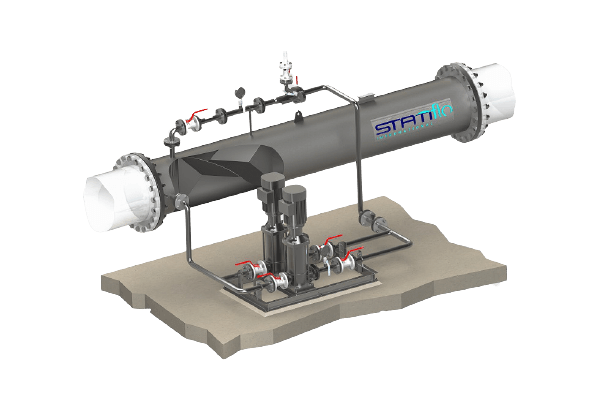

Static Mixers from STATIFLO, Manchester.

Static mixers are in line mixers that mixes two liquid medium using only the kinetic energy available in the flow stream. Statiflo Indonesia provides static mixers designed specifically for your mixing process that are highly efficient. Statiflo manufactures its products in Maccesfield Manchester and has its products sold in over 80 countries worldwide. All its mixers have been carefully designed for best efficiency and their designs have been rigorously tested in British Hydraulic Research Institute (BHR ltd). Using Statiflo Indonesia’s static mixer will save you chemical and power consumption as we can design the degree of mixing you need. Tell us and we will make it for you. The variables for design is mixer pipe size, the type of elements and the number of elements and the desired head loss. Statiflo have specialized computer design programmes to make this calculation a breeze.

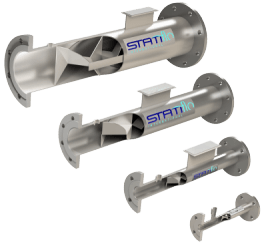

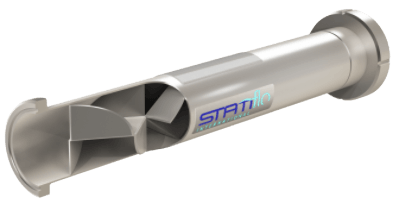

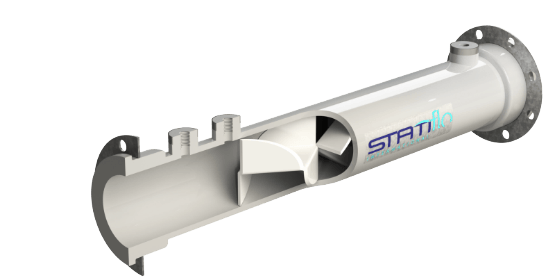

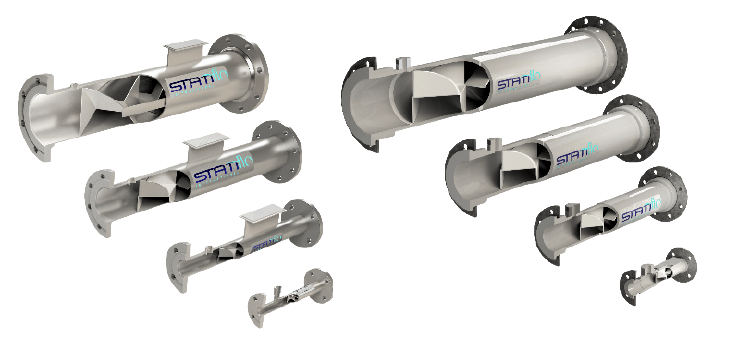

STATIFLO Series 100/150

Statiflo General Industrial Inline Static Mixers suitable for all process industries supplied with fixed or removable mixing elements.

- Usually supplied with SO or WN flanged end connections, but could equally be supplied with plain or weld prepared ends. Screwed/threaded end connections available for smaller sizes.

- Optional flanged or threaded injectors and sampling points. Optional heating/cooling jackets.

- Can be supplied in all commercially available metallic materials.

STATIFLO Series 200

- Sanitary Mixer: Sanitary and hygienic design Inline Static Mixers with removable elements suitable for use in food & drink, brewery and pharmaceutical applications as well as CIP (cleaning in place) systems.

- Complete with specialist sanitary surface finishes depending on your requirements.

- Supplied as standard with IDF, RJT, DIN, tri-clamp ferrule – or any other standard sanitary – end connections but flanged or plain ended options are also available.

- Can be supplied be injection/sample branches and heating/cooling jackets.

STATIFLO Series 300

Static Inline Mixers with solid PTFE removable mixing elements and PTFE lined carbon steel housing for corrosive duties in all industries. Also available with optional separate PTFE/PFA injection or sample tees.

Can be supplied with a choice of different PTFE-lined housings including painted carbon steel, stainless steel or others.

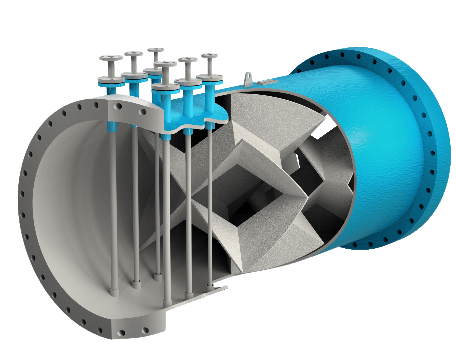

STATIFLO Series 600/650

- Statiflo Inline Static Mixers suitable for the water and wastewater treatment industries supplied with fixed mixing elements.

- Flanged or plain ended for VJ couplings with screwed end connections available for smaller sizes.

- Optional injectors and sampling points.

- Generally supplied in all stainless steel but for large diameters epoxy coated carbon steel is available for increased cost effectiveness.

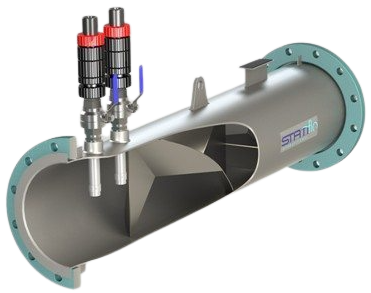

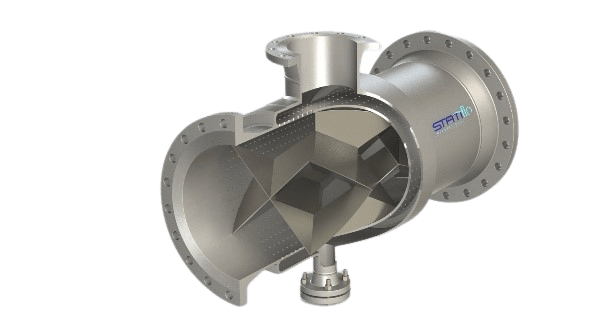

STATIFLO Series 800/850

Direct steam heaters in steel and exotic alloys for all industries. Fixed elements with integral steam injector or injector jacket.

The body of the actual mixer housing would be drilled with a series of steam injection holes to ensure that steam is injected radially around the mixer zone, to enable rapid and uniform dispersion of steam throughout water, resulting in rapid and efficient thermal heating.

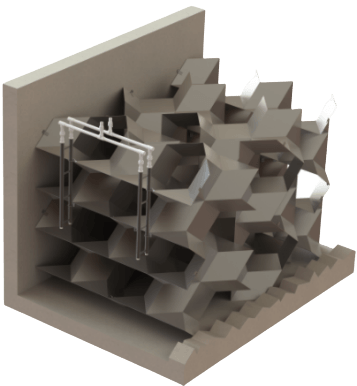

STATIFLO Channel Mixer

Conventional static mixing have been carried out in closed pipe systems. Sometimes open channel mixing is more convenient like in water treatment plants. Complete mixing is possible with a very low CoV or coefficient of variation for low or high flow rates. Statiflo Channel Mixers can be installed in new treatment works or easily retrofitted into existing installations, even when flooded and live. The modular design concept, based on the STMC mixing elements, allows wide variations in aspect ratio (height/width) suitable for square or nearly square channel sections, narrow deep channels and wide shallow channels. Independent trials have established that the STMC concept is the most efficient of all known commercially available static mixers. Statiflo Indonesia series 900 open channel static mixers have found many applications in water treatment plant like coagulant dosing, lime addition, polyelectrolyte addition, ph adjustment.

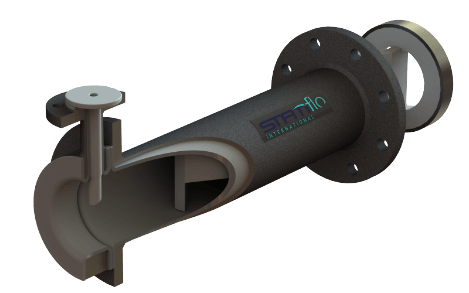

STATIFLO Non-Ragging (NR) Pipe Mixer

High performance non-ragging static mixer for difficult sludge and wastewater applications, specifically developed for flows with a high content of rags and/or highly fibrous material.

Typical Applications

- Sludge blending

- Sludge thickening

- Coagulant/Poly blending

- Ferric dosing for phosphorus removal

- Chemical dosing for raw sewage

- Product with fibres, e.g. Paperstock

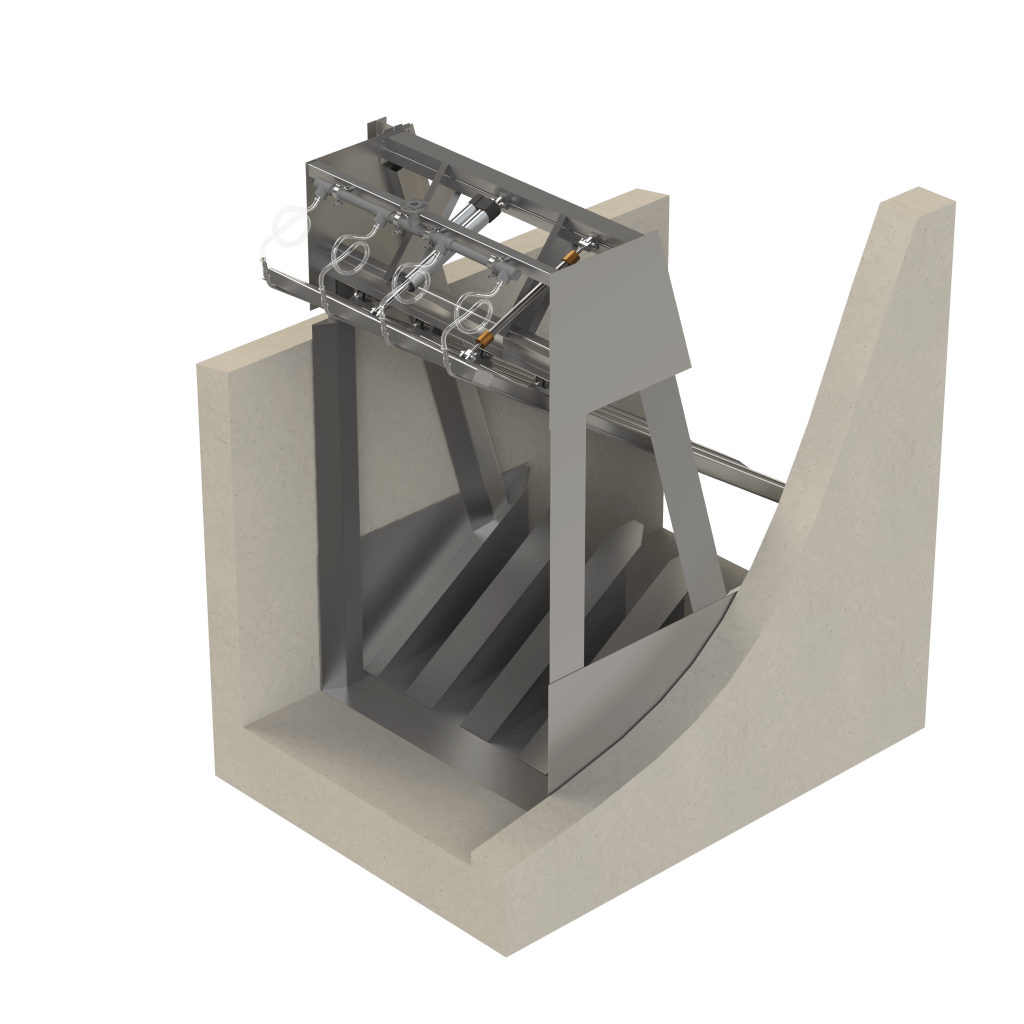

STATIFLO Non-Ragging Channel (NCR) Mixer

NRC’s unique variable geometry custom designed for the widest range of wastewater velocities and channel depths found on a typical wastewater treatment plant.

FITURES:

- Variable angle control vanes tuned to optimise performance within tight headloss constraints

- Subsurface fixed vanes to aid mixing at low depth

- Adaptable design for a wide range of channel sizes, aspect ratios, water depths and flow rates

- No direct power requirements for mixing

- Available with automatic (power required) or manual (no power required) control vane options

- Accessible integrated sparger for chemical injection

- Designed for easy installation into open channel

- Custom designed for each application

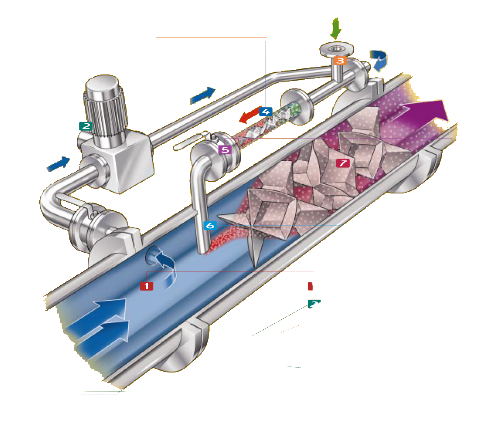

STATIFLO Gas Dispersion System

Statiflo Indonesia presents a new concept of mixing gas with a liquid for simultaneous mixing and mass transfer. For mass transfer, the particle size has to be small. To shear gas bubbles in a normal pipe static mixer may involve a large amount of energy. In order to reduce energy a side stream is used where very high shear is applied resulting in very small bubble size. This side stream is then added to the main stream where normal shear is applied to maintain the bubble size and thus maximize mass transfer. Applications for drinking water plants are ozone dissolution, carbonation of mineral water.

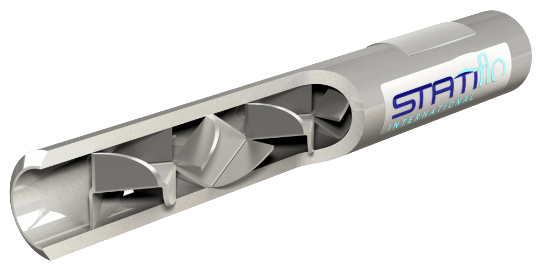

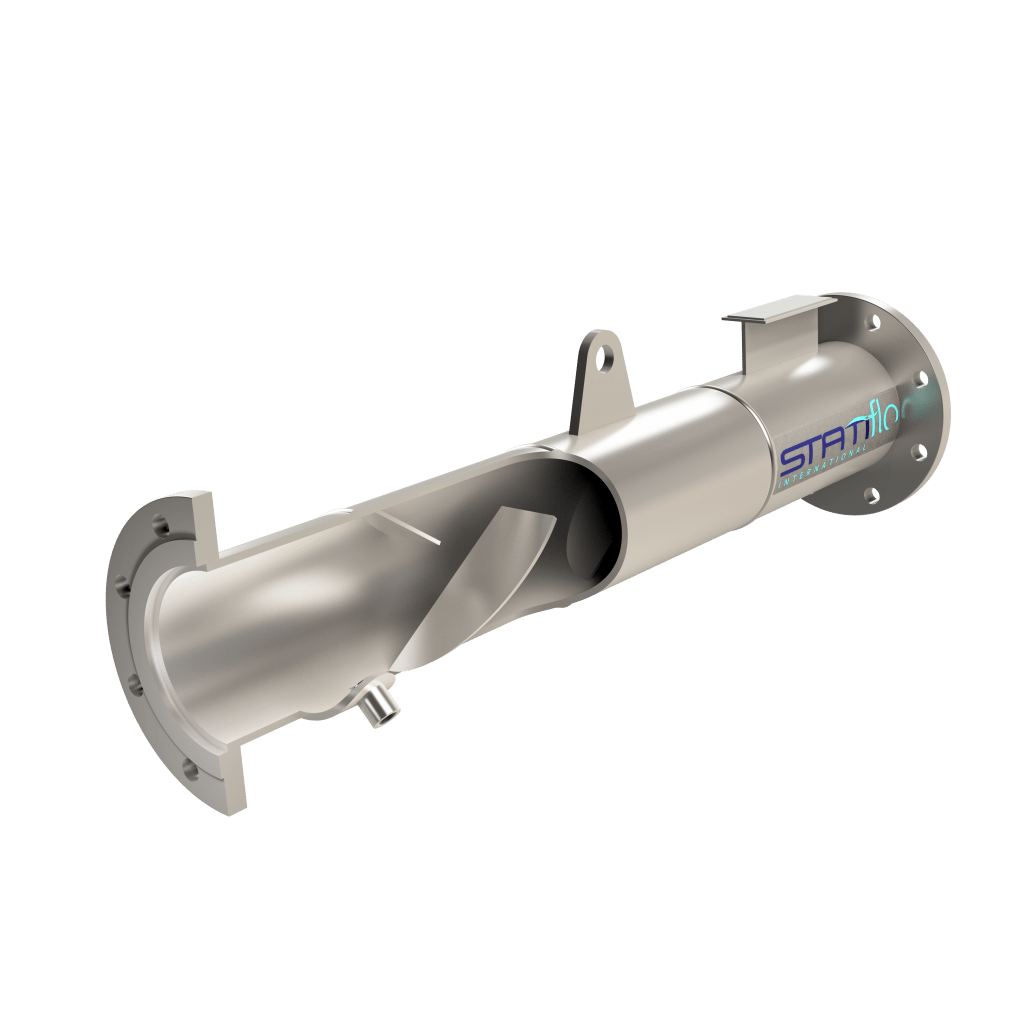

STATIFLO Gas Static Mixer

Statiflo Indonesia designs special mixers for gas flows. These mixers create maximum turbulence with low head loss ideal for mixing in the oil and gas industries. These mixers can be fabricated with materials that are corrosion resistant like Inconel titanium and pvc. The head loss and degree of mixing can be adjusted to suit your application. Gas static mixers can also be used for stabilizing flow for better contact with catalysts where consistent gas velocities is important. Here the linearization of flow velocities to create a laminar flow regime is important instead of highly turbulent flow regimes needed for mixing. Other applications are for mixing of regions of low and high concentrations of particulates to comply with emission standards. Gas static mixers are also important to make a homogeneous mixture for NOx reduction in catalytic gas reactors.