DYNAMIC MIXER

Dynamic in Line Mixer by INDAG

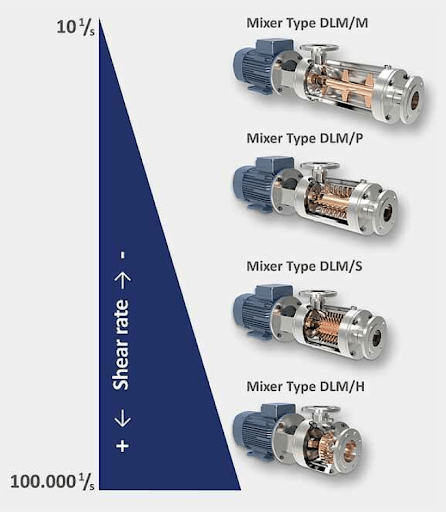

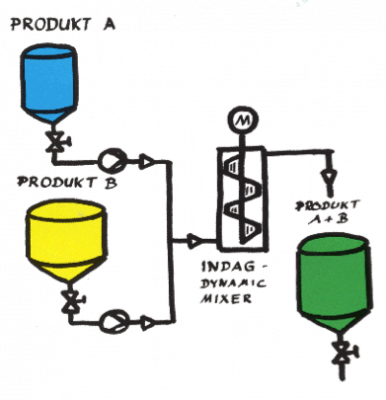

Indag Indonesia supplies a range of dynamic in line mixers for your mixing and homogenizing needs. Dynamic mixers are highly efficient method of blending two liquids together as they do not have to move around huge volumes of liquid as in normal tank mixing. This saves a huge amount of kinetic energy. Even so the coefficient of variation of the mixed products is better in a dynamic mixer unless a high quality efficient and expensive in tank mixer is chosen. This is because there are no dead areas in dynamic inline mixer so often found in in tank mixing. Indag Indonesia’s dynamic mixers are ideal for mixing a diverse range of liquids form low to high viscosity, with or without solids. The degree of shear can also be varied to suit your manufacturing needs and they can range from high shear needed for making soaps to low shear for making food ingredients. The manufacturing plant footprint is also reduced as no large tanks is needed. The only caution is that the proportion of mix fed into the in line mixer has to be controlled carefully.

In Line Dynamic Mixers with Low Shear

Model DLM

Indag produces a line of low shear in line dynamic mixers. Model DLM. They are used by multi nationals to make products like fruit yogurt, paints, addition of polymers to sludge, chocolate, bitumen and beverages. This range of mixers is designed to give efficient mixing without excessive shearing force. Excessive shearing force is sometimes not desirable for example in blending additives to shear sensitive emulsions like yoghurt. The degree of shear can be adjusted by the innovative design of the impellers. The Indag mixer is made in a solid construction expected from a German machine and has full access to all internal parts for cleaning. In short it has been manufactured in hygienic execution suitable for food and pharmaceutical applications. Sealing of the mixing compartment can be by hygienic single mechanical or double mechanical seal or with water flush design. The pressure is 6 bars standard and material execution can be of stainless steel to plastics, to Teflon coated steel. For proper selection of the right machine ask the friendly Arasains Indonesia staff.

In Line Intensive Dynamic Mixers

Model DLM/S

Indag from Germany supplies a range of intensive dynamic mixers for the Indonesian market. These equipment are designed to give efficient mixing but with a high degree of shear. The amount of shear however is adjustable and must designed to give you just the right amount to homogenize your product. Applications of these machine is for blending of high viscosity solid rubber solutions or for soap making. The Indag mixer is made in a solid construction expected from a German machine and has full access to all internal parts for cleaning. In short it has been manufactured in hygienic execution suitable for food and pharmaceutical applications. Sealing of the mixing compartment can be by hygienic single mechanical or double mechanical seal or with water flush design. The pressure is 6 bars standard and material execution can be of stainless steel to plastics, to Teflon coated steel. For proper selection of the right machine ask the friendly Arasains Indonesia staff.

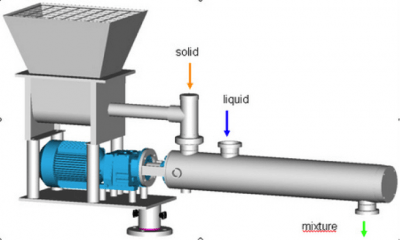

In Line Dynamic Mixer with Grinder or Shredder Model DLM/R

Indag supplies a line of high shear dynamic mixers for refining, milling or shredding of solids in liquid medium. As well as performing the function of cutting the fibers, this equipment also serve to increase the total surface area of products available for reaction as in bio reactors.

Large surface areas reduces reaction and process time. The design of the cutter are adapted for different tasks for fibers to particulates. The wear edges of the cutters have been hardened by German technology to give long life. The gap between the rotor and stator can be varied to suit the particle sizes of the product intended for size reduction. Indag from German mixer can be designed for small capacities to very large with capacities from 10L/hr to 120,000 L/hr. Operating pressure is 6 bar standard and up to 120 bar on request. Sealing can be single or double mechanical seals or with magnetic coupling.

In Line Dynamic Mixers for Heat Exchange

Model DLM/WT

Heat exchange for high viscosity products are difficult resulting in poor heat exchange. Indag supplies heat exchangers with wiped surfaces. A series of blades wipe the heat exchange surfaces and pushes the product to the center. In this way the heated product is removed from the heat exchange surface and fresh product is replaced. These equipment can be for heating or cooling. The degree of shear can be controlled by innovative design of the scraper blades.

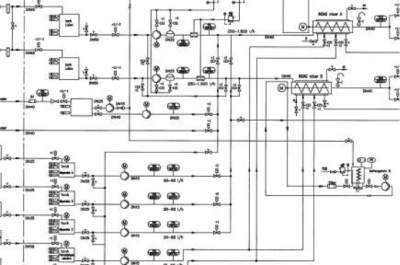

Complete Units of Dynamic Mixing Skid

Indag supplies all of the above mixing unit operations in a mounted skid. These skids can come complete with dosing pumps and mass flow meters to correctly proportionate your ingredients and feed them into the in line dynamic mixer. These skids can be used for dosing of vitamins to palm oil, blending of shampoo to be used as compact production units, for dilution of high viscosity surfactants. Another application of these skids is for foaming of food ingredients, pharmaceuticals and latex examples of which are whipped creams, cake fillings, latex mattress chocolates.