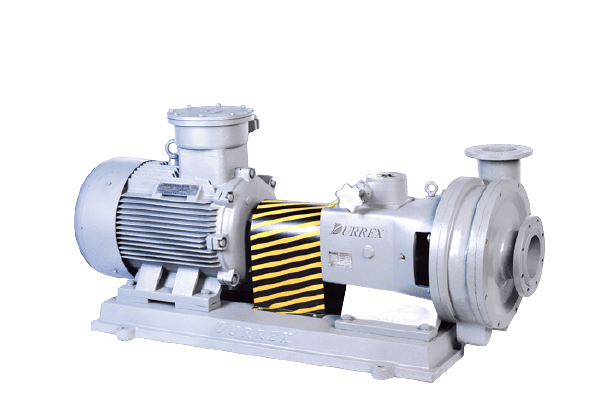

HOMOGENIZER

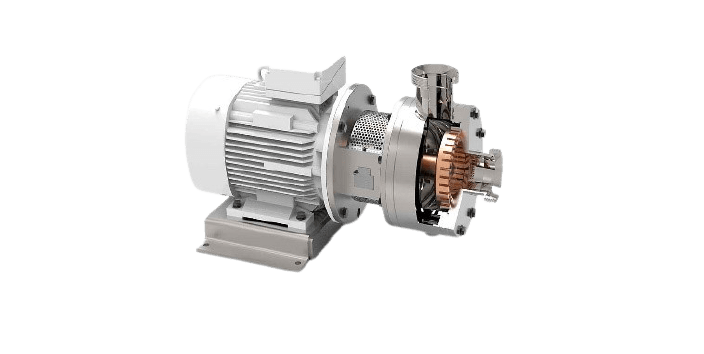

Homogenizer DLM/H

by INDAG

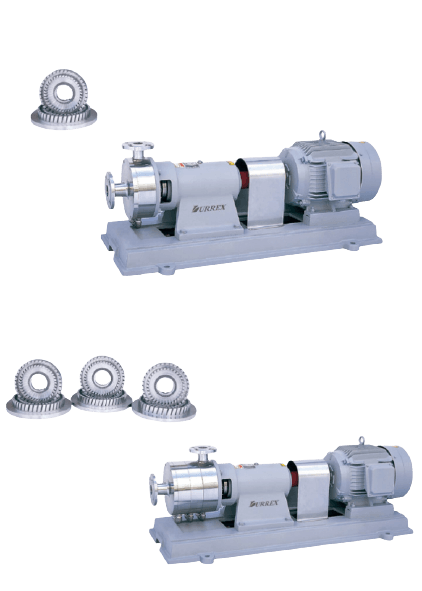

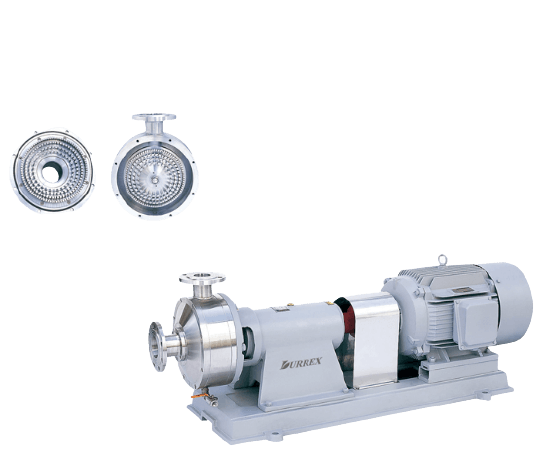

The INDAG homogenizer type DLM/H is used for effective dispersion (emulsification) and for the production of a suspension from liquids and solids. In addition, solids in liquids can be broken up. Examples of the use of the DLM/H are: the production of stable emulsions from oil + water + emulsifier; diluting sodium lauryl ether sulfate (SLES) + water; the production of paints, varnishes, detergents, adhesives. With an INDAG DLM/H the process time is shortened and the product quality is improved compared to batch systems.

Benefit of this equipment is very good self-cleaning during CIP cleaning, efficient input of mixed energy, modular structure of the machine, hygienic construction

INDAG homogenizer can be installed horizontally or vertically, and has pressure levels: 6 bar, 10 bar, 16 bar, 25 bar, 40 bar, 100 bar. It can handle viscosities: 1 mPas to 500,000 mPas with temperature: 0 °C to 300 °C