PRODUCT DETAILS

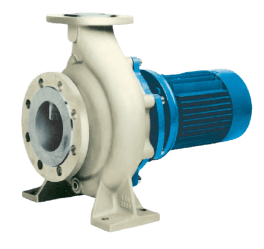

Centrifugal pumps. Johnson pumps-Part of SPX group- a fortune 500 company

The centrifugal pump is the most common pump used in industry. The centrifugal pump converts kinetic energy into potential energy by a rotating impeller. The centrifugal force increases the fluid velocity as it flows along the impeller alongside the blades and at the outlet this energy is converted to pressure energy. Johnson pumps offer a wide range of centrifugal pumps and are made in Sweden, Belgium, Holland, USA and India.

Johnson pump’s combi system is a modular programme of centrifugal pumps with a high degree of interchangeability between different series of pumps. This allows many variants to be built to cover the complete range and allow proper selection for each specific application. Johnson pumps are available in ATEX, 3A, EHEDG, FDA, USP VI with material traceability and certification 2.1, 2.2, and 3.1. Tests such as QHP, vibration tests, and noise levels can be arranged.

Combi bloc centrifugal pump – Johnson a SPX flow technology brand

This is a single stage closed coupled centrifugal pump produced to EN733 (DIN 24255). This pump is compact economical and has a small footprint. No shaft alignment is required and has outstanding hydraulic performance. The impeller is supplied with a high efficiency closed impeller with back vanes giving axial balancing of impeller loads.

Maintenance is easy with low maintenance and installation is easy without a baseplate. ATEX certification is available and vertical arrangement is possible. The standard seal is mechanical according to EN12756 (DIN 24690). This pump is suitable for clean, fluids with low viscosity or slightly contaminated fluids. The casing is cast iron, bronze or stainless steel. The impeller is cast iron, bronze or stainless. The max capacity is 850m3/hr at 10 bar.

Centrifugal pumps. Johnson pumps-Part of SPX group- a fortune 500 company

The centrifugal pump is the most common pump used in industry. The centrifugal pump converts kinetic energy into potential energy by a rotating impeller. The centrifugal force increases the fluid velocity as it flows along the impeller alongside the blades and at the outlet this energy is converted to pressure energy. Johnson pumps offer a wide range of centrifugal pumps and are made in Sweden, Belgium, Holland, USA and India.

Johnson pump’s combi system is a modular programme of centrifugal pumps with a high degree of interchangeability between different series of pumps. This allows many variants to be built to cover the complete range and allow proper selection for each specific application. Johnson pumps are available in ATEX, 3A, EHEDG, FDA, USP VI with material traceability and certification 2.1, 2.2, and 3.1. Tests such as QHP, vibration tests, and noise levels can be arranged.

Frequently Asked Questions

-

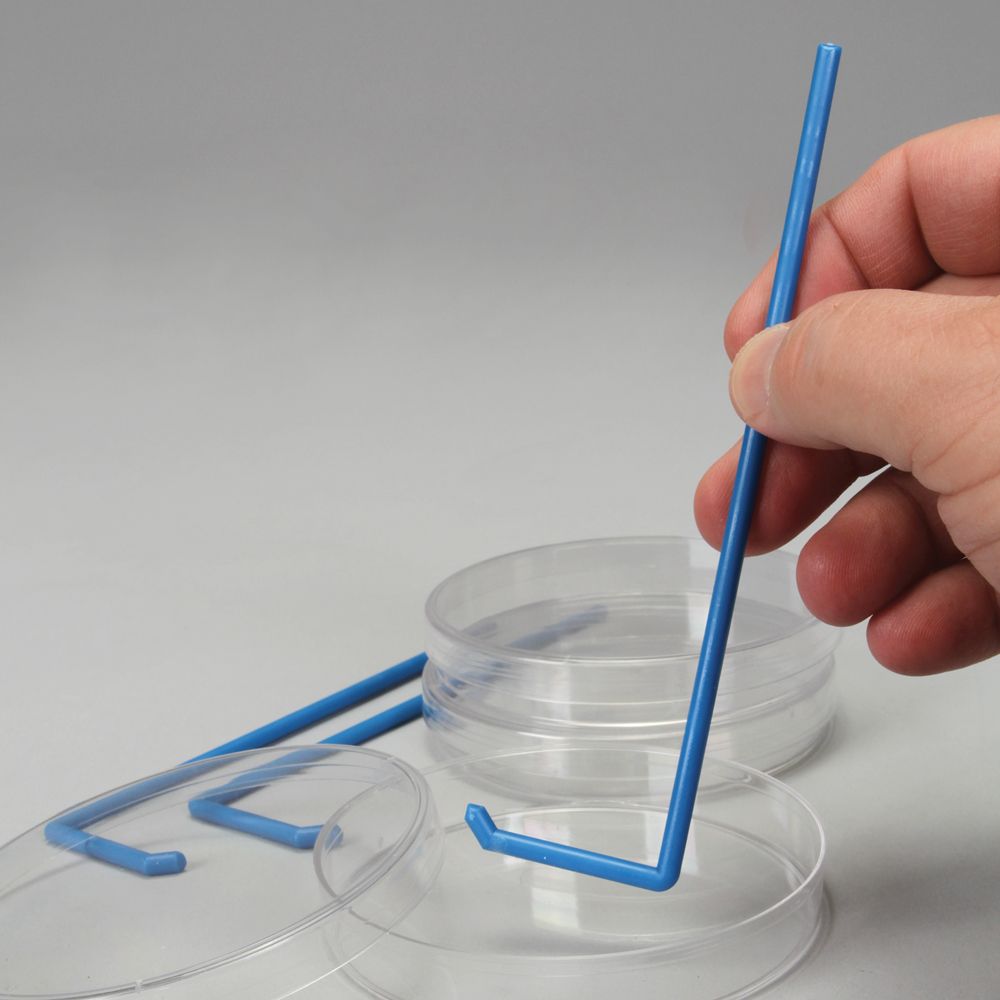

What is the advantage of using Eliza technology for Listeria?

Identification of the bacteria is easier and more specific. There is no need to look for haemolysis.

-

Title or question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links. -

Title or question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

Video

To Get More Information

Don't Hesitate to Contact Us

Company Address

Rukan Kirana Boutique Office

Blok F3 no 12, Boulevard Raya No.1 Kelapa Gading. Jakarta Utara

Indonesia, 14240

Contact

+6221 4585 8833

info@arasains.co.id

Quick Link

Product Link

Copyright (c) 2021 PT Arasains. All Right Reserved